Analysis of Tungsten Cylinder : Performance, Manufacturing and Applications

Cylindrical components made of tungsten heavy alloys (such as WHA) are engineering components that combine high density, excellent mechanical properties, and good machinability. The following section introduces them from three aspects: material composition, manufacturing process, performance characteristics, and applications.

Material Composition and Manufacturing Process:

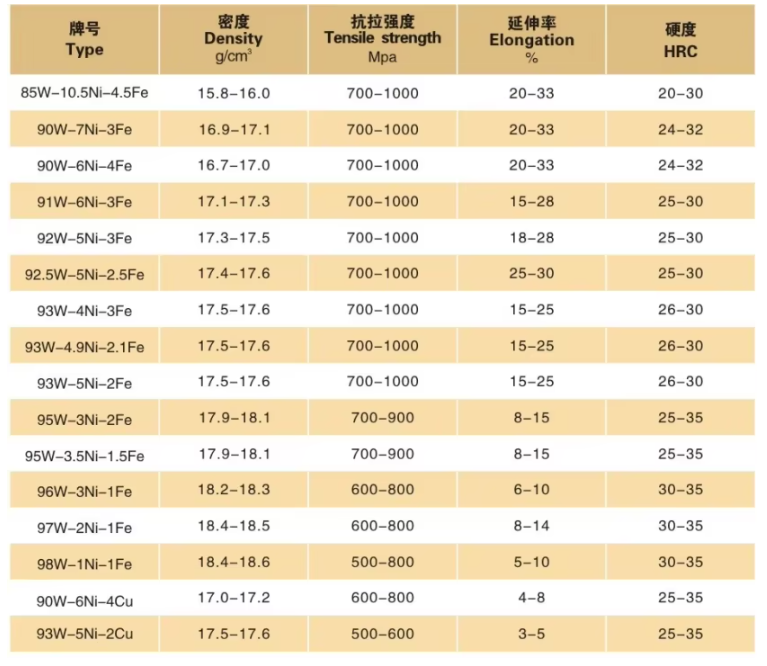

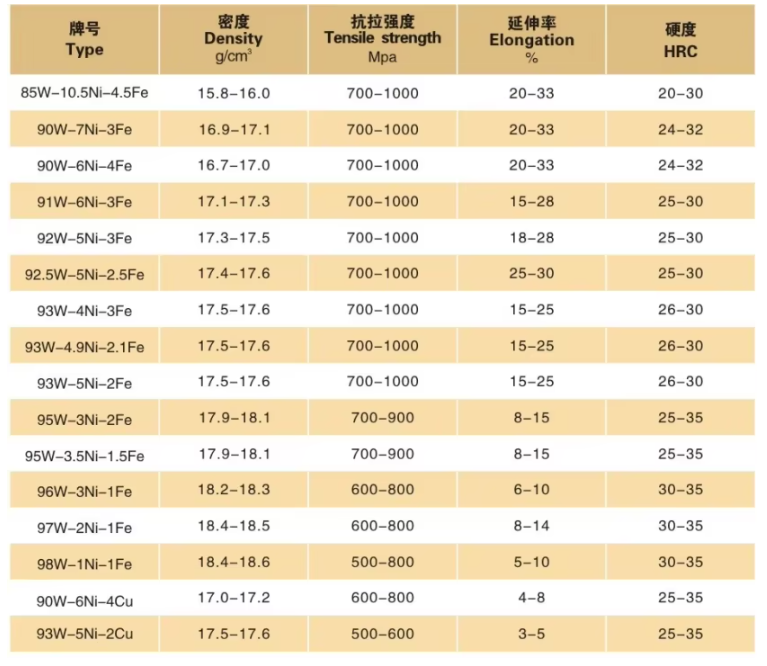

1.Tungsten heavy alloys are typically made with tungsten (W) as the main component, with nickel (Ni), iron (Fe), and copper (Cu) added as binder phases.

2.A typical composition is 95% W + 3.5% Ni + 1.5% Fe, with a density reaching approximately 18 g/cm³.

3.The manufacturing process generally involves: powder metallurgy → pressing → sintering → (possibly) subsequent heat treatment and machining. This method allows for the production of various shapes, including cylinders, rods, blocks, and plates.

Performance characteristics:

1.Perfomance characteristics: High density: Typical values range from 16.8 to 18.5 g/cm³ .

2.Good mechanical strength and certain toughness: While still exhibiting the tendency of "heavy alloys = hard and brittle," its toughness is improved compared to pure tungsten.

3.Thermal stability and radiation shielding ability: Due to its high density and the characteristics of tungsten, it performs excellently under heat loads and radiation environments.

4.Low coefficient of thermal expansion: Beneficial for dimensional stability.

Application Scenario:

1. Counterweights and balancing components: Counterweight cylinders used in aircraft, helicopters, racing cars, and ships, whose high density allows for the achievement of required mass even in space-constrained environments.

2. Shielding and protective materials: Such as radiation shielding components in medical imaging equipment and nuclear facilities.

3. Heavy-duty shafts, pins, and supports: Components requiring high mass and load capacity in extreme environments.

4. Molds and wear-resistant components: Tungsten heavy alloys can also be used in tool or mold components for high-wear, high-temperature applications.

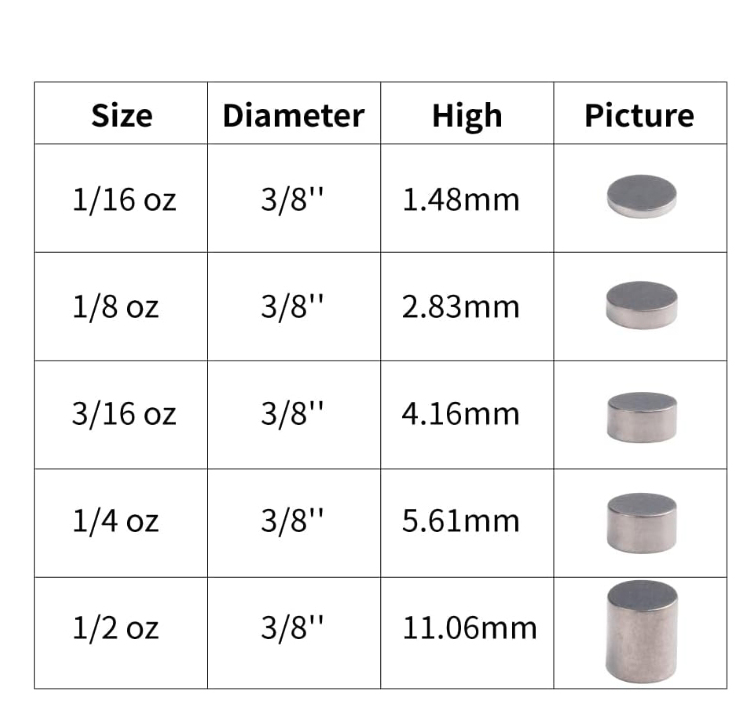

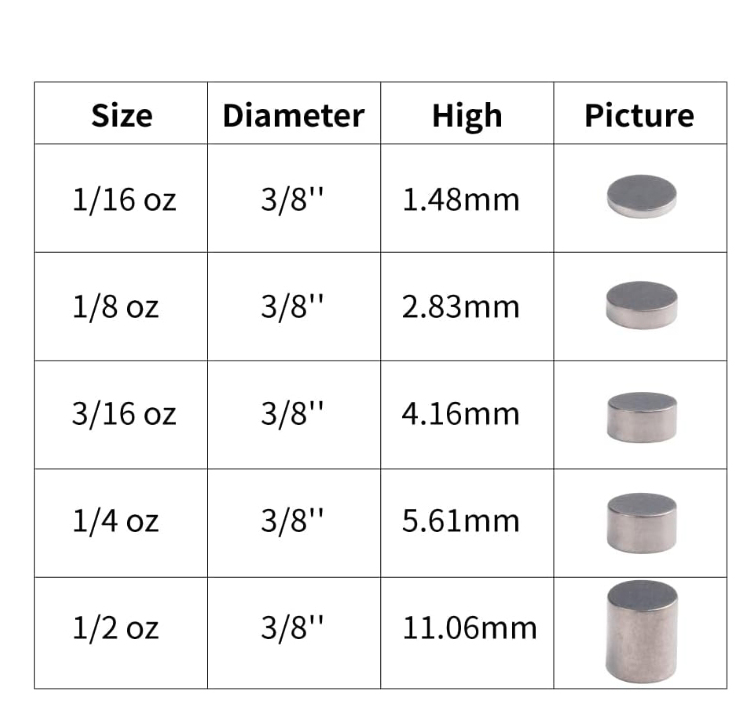

Size and Grade:

Product Show:

Hard alloy cylindrical parts made of tungsten heavy alloy have significant advantages in many industrial fields due to their high density, high strength, excellent thermal stability and dimensional controllability.