Product Detail Description:

Elevate Your Precision Machining with Premium W-Cu Alloys

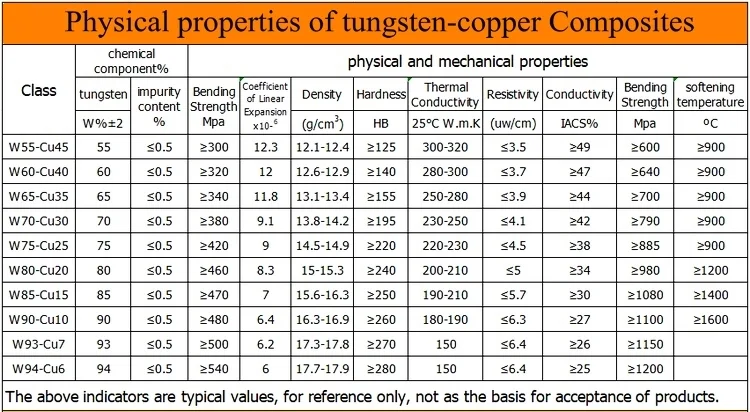

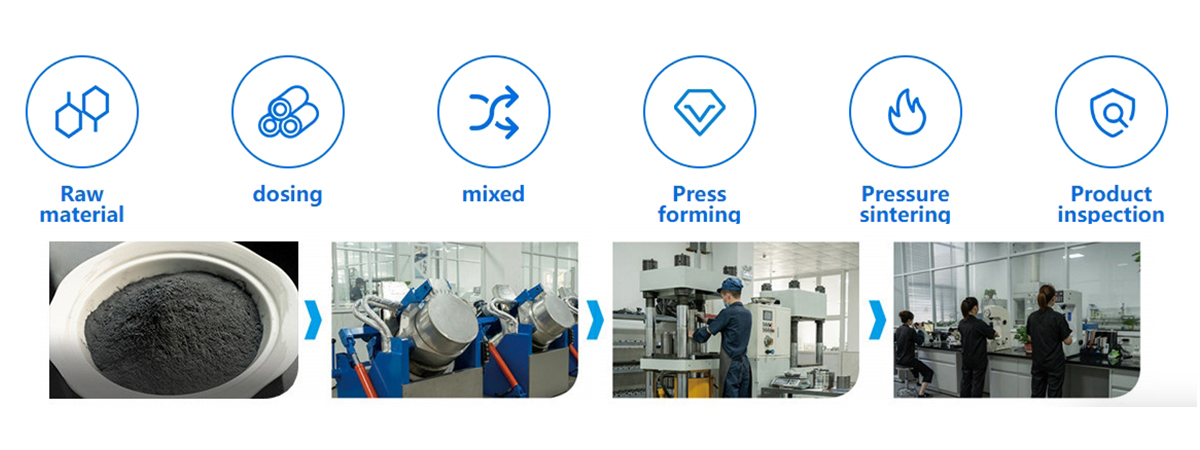

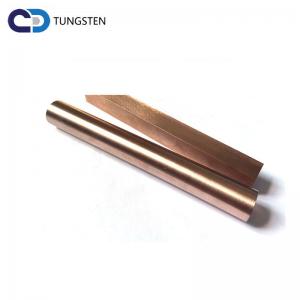

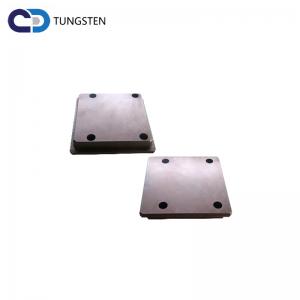

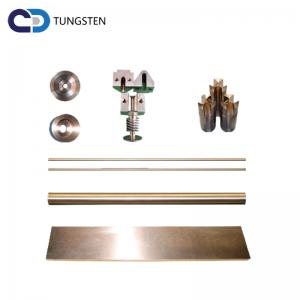

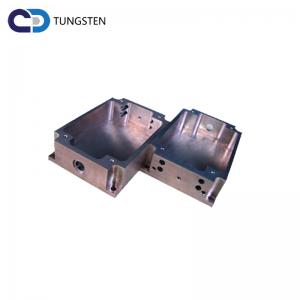

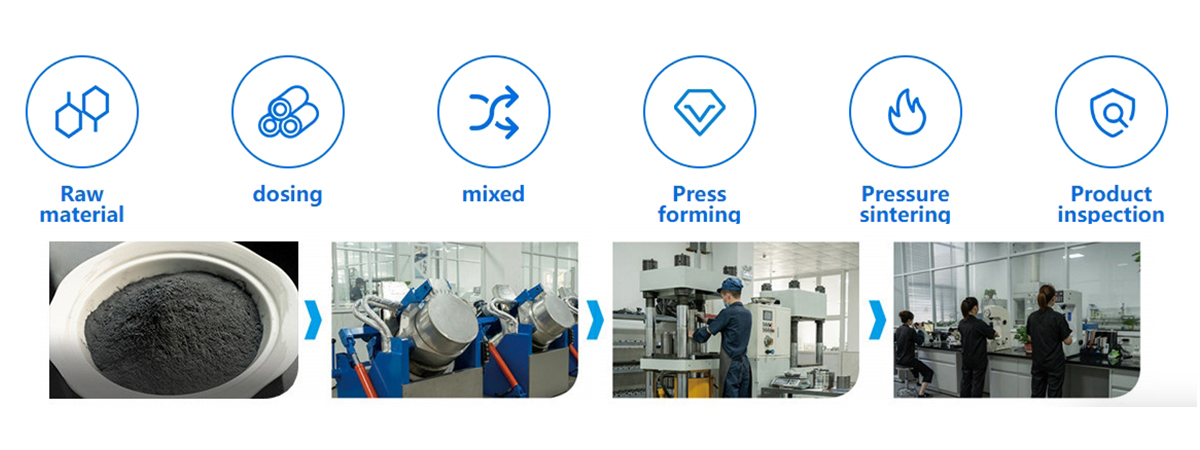

Our Tungsten Copper (W-Cu) alloy components are manufactured using an advanced vacuum infiltration process, ensuring a perfectly uniform microstructure. By combining the high melting point of Tungsten with the superior electrical conductivity of Copper, these parts are engineered for the most challenging EDM (Electrical Discharge Machining) and thermal management tasks.

Key Technical Advantages:

Optimal Density & Hardness: Provides excellent wear resistance and reduces electrode loss during high-speed machining.

Superior Thermal Management: Rapid heat dissipation ensures dimensional stability under extreme temperatures.

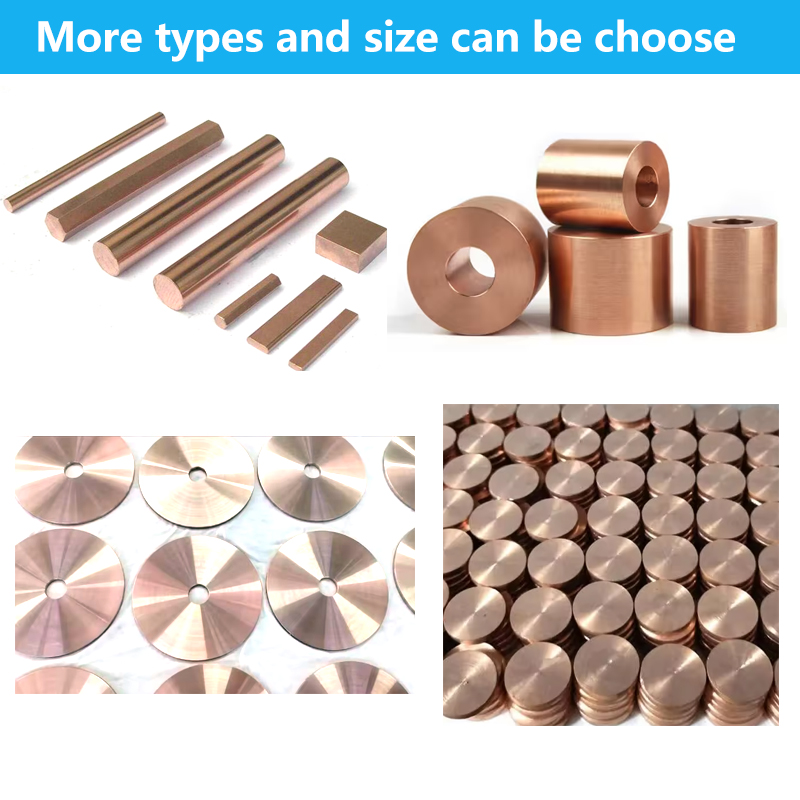

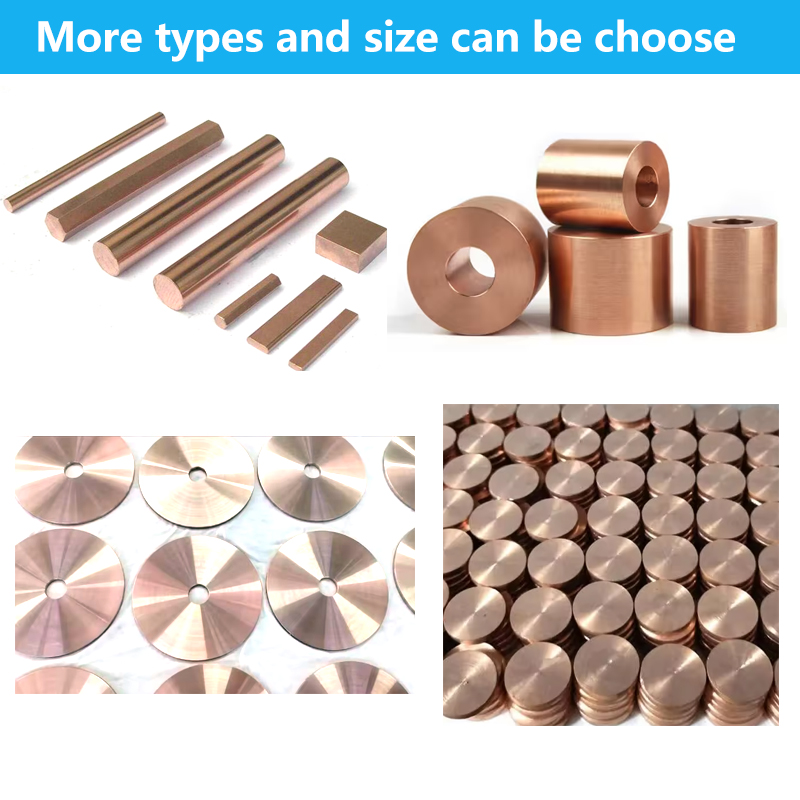

Precision Tolerances: Available in specialized sizes such as $\Phi 22-\Phi 15-23$ and $\Phi 23-\Phi 12-13$ to fit your specific mold designs.

High Arc Resistance: Ideal for high-voltage electrical contacts and heavy-duty industrial applications.

Why Choose Our W-Cu Components?

Consistent Performance: Uniform material density prevents localized wear and premature failure.

Enhanced Surface Finish: Achieve superior workpiece results thanks to stable and consistent spark discharge.

Versatile Applications: Perfect for EDM electrodes, resistance welding, and high-temperature mold inserts.

Flexible Specifications: We offer a wide range of outer diameters ($\Phi 22$ to $\Phi 23$) and customizable lengths to match your machinery.

Hoekom ons kies:

1. Jy kan die perfekte materiaal volgens jou vereiste teen die minste moontlike prys kry.

2. Ons bied ook Reworks, FOB, CFR, CIF, en deur tot deur afleweringspryse. Ons stel voor dat u 'n transaksie doen vir versending wat redelik ekonomies sal wees.

3. Die materiaal wat ons verskaf is heeltemal verifieerbaar, reg van grondstoftoetssertifikaat tot die finale dimensionele verklaring.(Verslae sal op vereiste wys)

4. waarborg om binne 24 uur 'n antwoord te gee (gewoonlik in dieselfde uur)

5. Jy kan voorraadalternatiewe kry, meulaflewerings met die minimalisering van vervaardigingstyd.

6. Ons is ten volle toegewyd aan ons kliënte. As dit nie moontlik sal wees om aan u vereistes te voldoen nadat u alle opsies ondersoek het nie, sal ons u nie mislei deur valse beloftes te maak wat goeie kliënteverhoudings sal skep nie.

Fabrieksvertoning

KONTAK ONS

info@zztungsten.com