Product Detail Description:

Elevate Your Precision Machining with Premium W-Cu Alloys

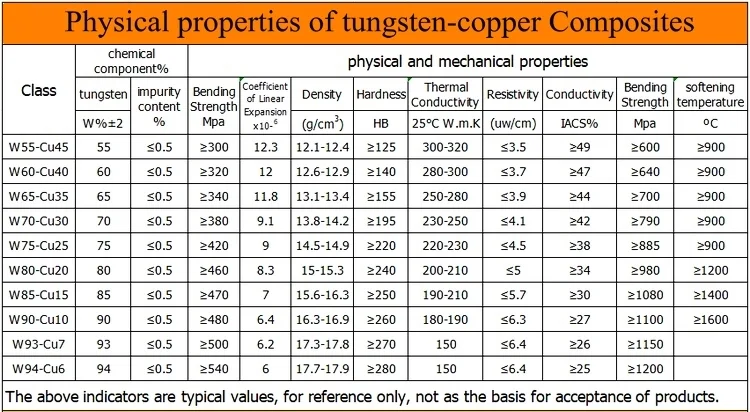

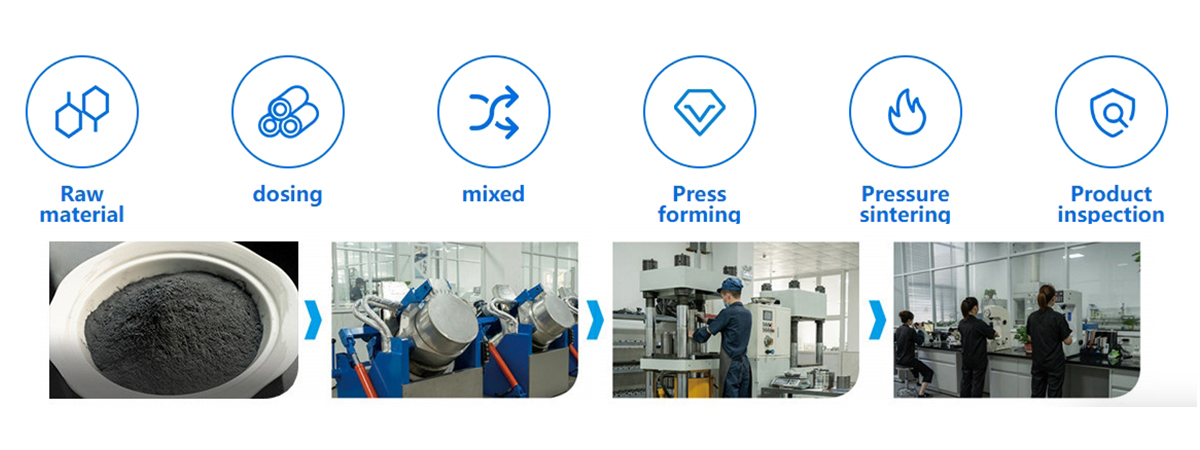

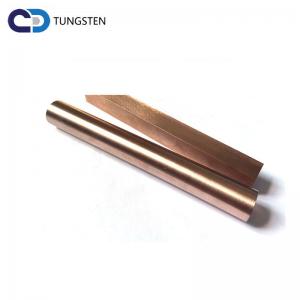

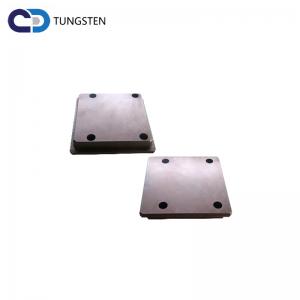

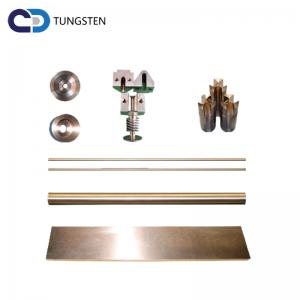

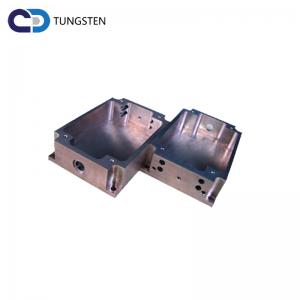

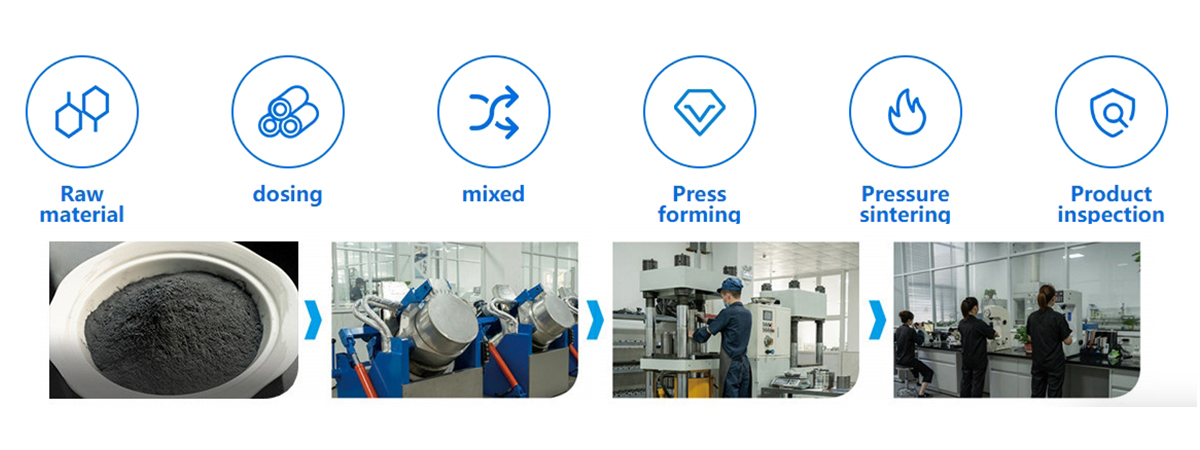

Our Tungsten Copper (W-Cu) alloy components are manufactured using an advanced vacuum infiltration process, ensuring a perfectly uniform microstructure. By combining the high melting point of Tungsten with the superior electrical conductivity of Copper, these parts are engineered for the most challenging EDM (Electrical Discharge Machining) and thermal management tasks.

Key Technical Advantages:

Optimal Density & Hardness: Provides excellent wear resistance and reduces electrode loss during high-speed machining.

Superior Thermal Management: Rapid heat dissipation ensures dimensional stability under extreme temperatures.

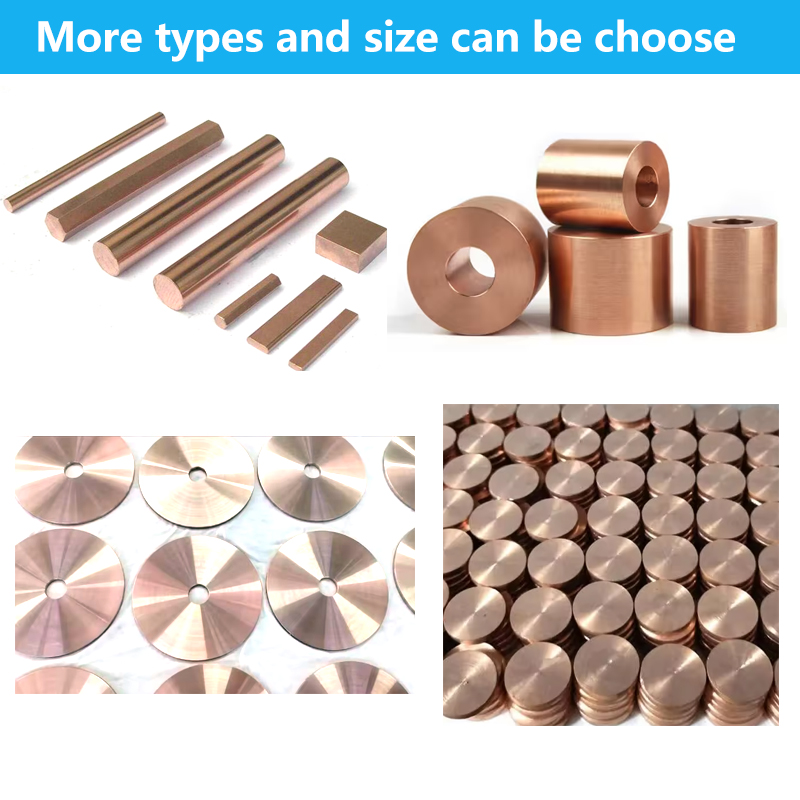

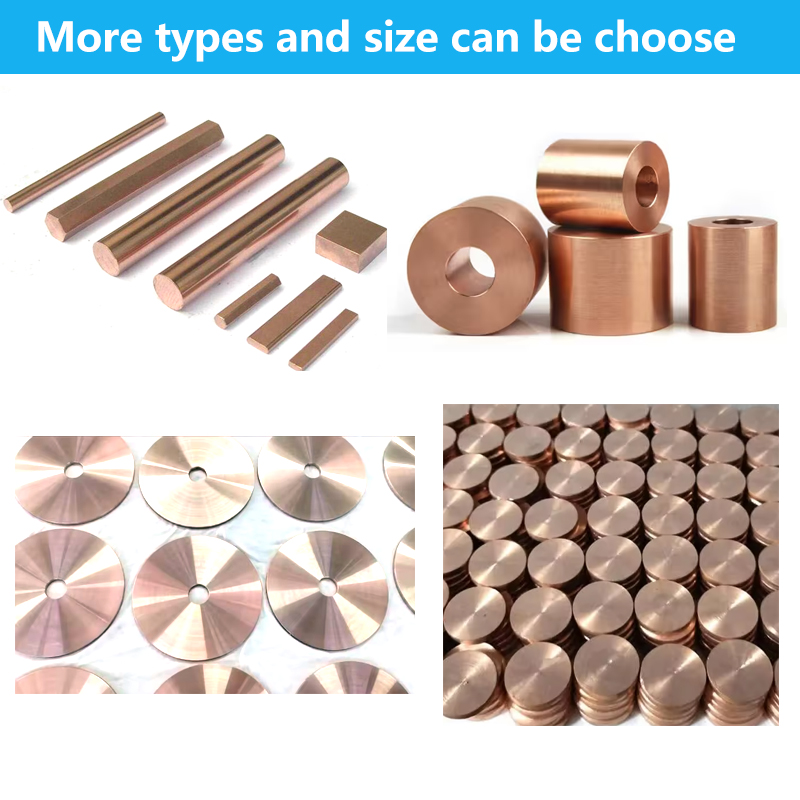

Precision Tolerances: Available in specialized sizes such as $\Phi 22-\Phi 15-23$ and $\Phi 23-\Phi 12-13$ to fit your specific mold designs.

High Arc Resistance: Ideal for high-voltage electrical contacts and heavy-duty industrial applications.

Why Choose Our W-Cu Components?

Consistent Performance: Uniform material density prevents localized wear and premature failure.

Enhanced Surface Finish: Achieve superior workpiece results thanks to stable and consistent spark discharge.

Versatile Applications: Perfect for EDM electrodes, resistance welding, and high-temperature mold inserts.

Flexible Specifications: We offer a wide range of outer diameters ($\Phi 22$ to $\Phi 23$) and customizable lengths to match your machinery.

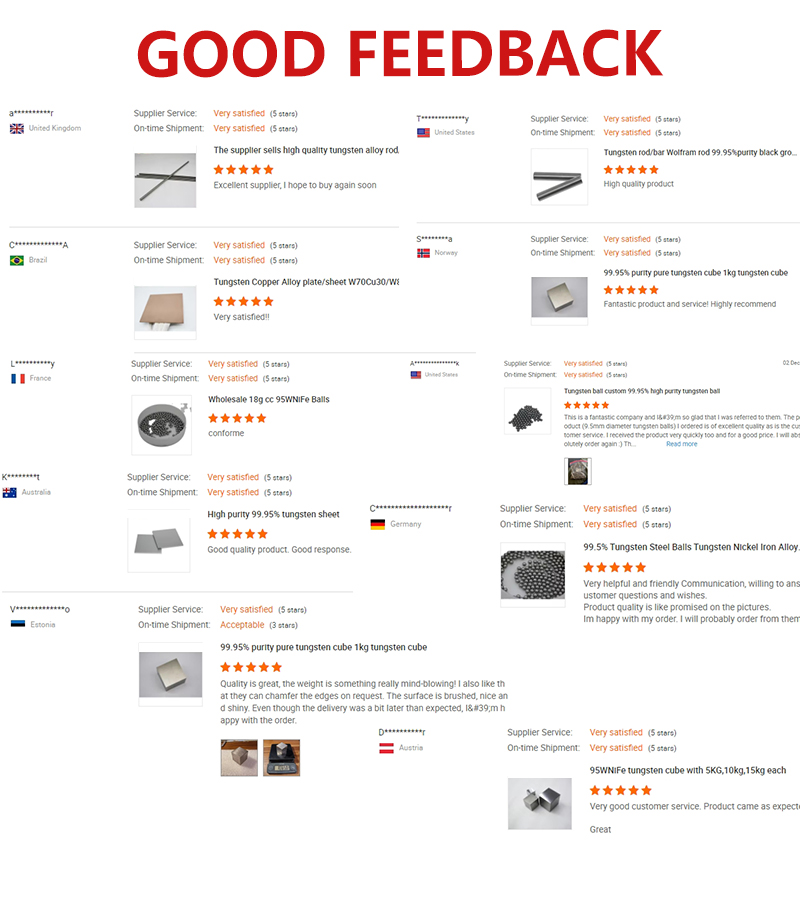

Hvorfor vælge os:

1. Du kan få det perfekte materiale i henhold til dine krav til den mindst mulige pris.

2. Vi tilbyder også Reworks, FOB, CFR, CIF og dør til dør leveringspriser. Vi foreslår, at du gør en aftale om forsendelse, som vil være ret økonomisk.

3. De materialer, vi leverer, er fuldstændigt verificerbare, lige fra råmaterialetestcertifikat til den endelige dimensionserklæring. (Rapporter vises efter behov)

4. garanti for at give et svar inden for 24 timer (normalt i samme time)

5. Du kan få lageralternativer, mølleleverancer med minimering af fremstillingstid.

6. Vi er fuldt dedikerede til vores kunder. Hvis det ikke er muligt at opfylde dine krav efter at have undersøgt alle muligheder, vil vi ikke vildlede dig ved at give falske løfter, som vil skabe gode kunderelationer.

Fabriksdisplay

KONTAKT OS

info@zztungsten.com