Product Detail Description:

Elevate Your Precision Machining with Premium W-Cu Alloys

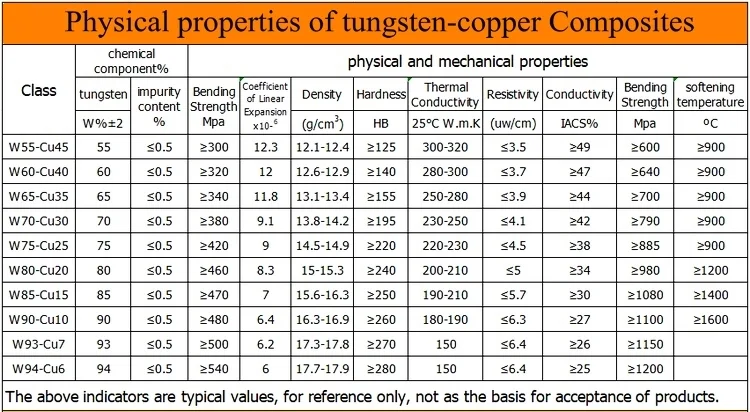

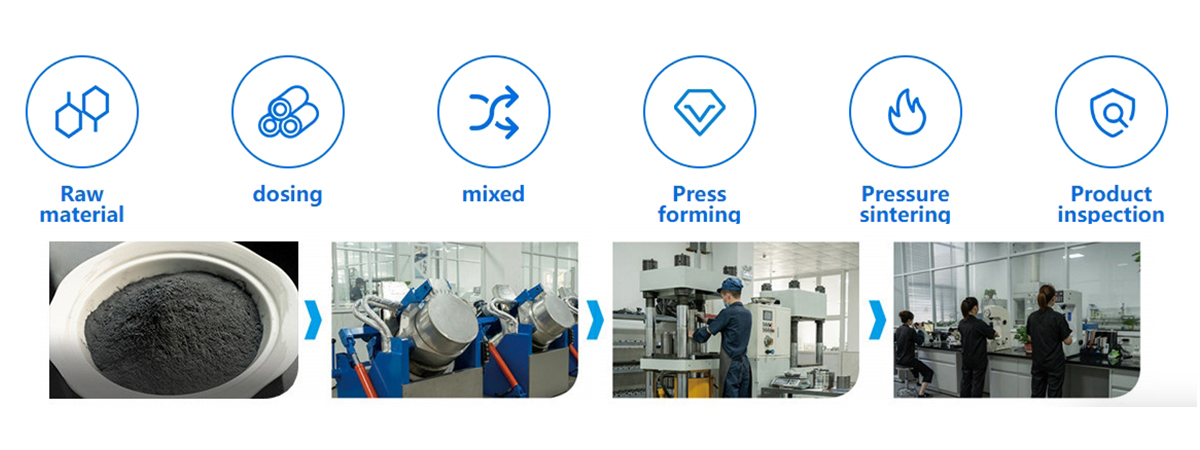

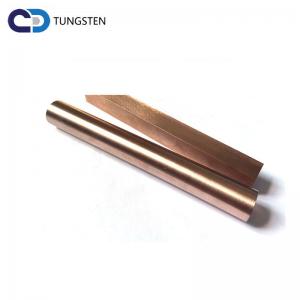

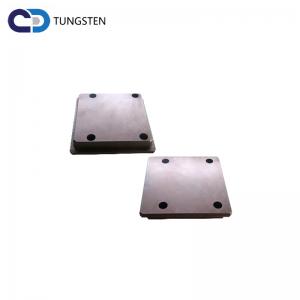

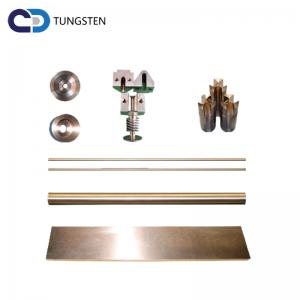

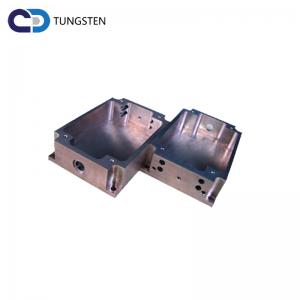

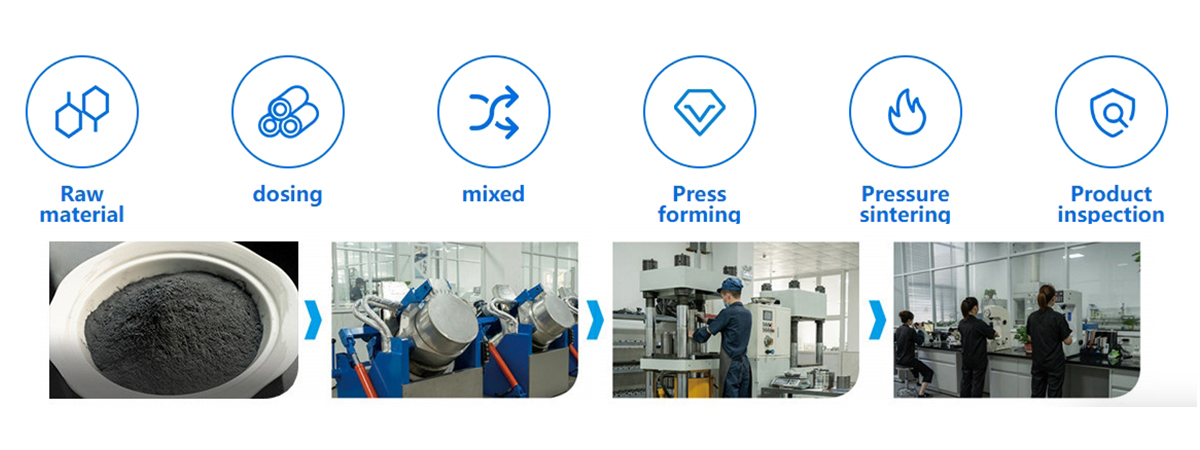

Our Tungsten Copper (W-Cu) alloy components are manufactured using an advanced vacuum infiltration process, ensuring a perfectly uniform microstructure. By combining the high melting point of Tungsten with the superior electrical conductivity of Copper, these parts are engineered for the most challenging EDM (Electrical Discharge Machining) and thermal management tasks.

Key Technical Advantages:

Optimal Density & Hardness: Provides excellent wear resistance and reduces electrode loss during high-speed machining.

Superior Thermal Management: Rapid heat dissipation ensures dimensional stability under extreme temperatures.

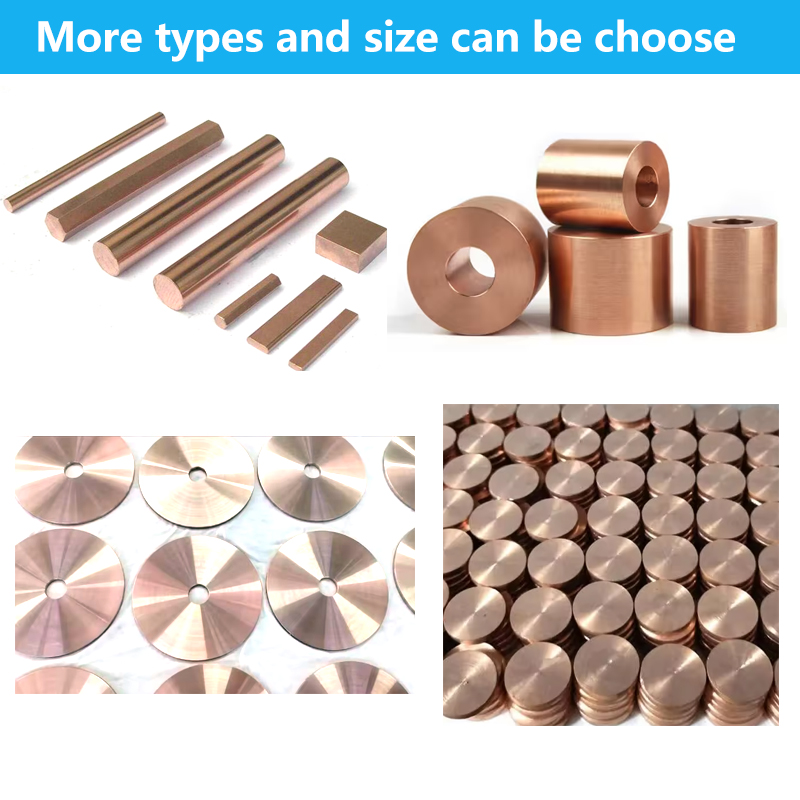

Precision Tolerances: Available in specialized sizes such as $\Phi 22-\Phi 15-23$ and $\Phi 23-\Phi 12-13$ to fit your specific mold designs.

High Arc Resistance: Ideal for high-voltage electrical contacts and heavy-duty industrial applications.

Why Choose Our W-Cu Components?

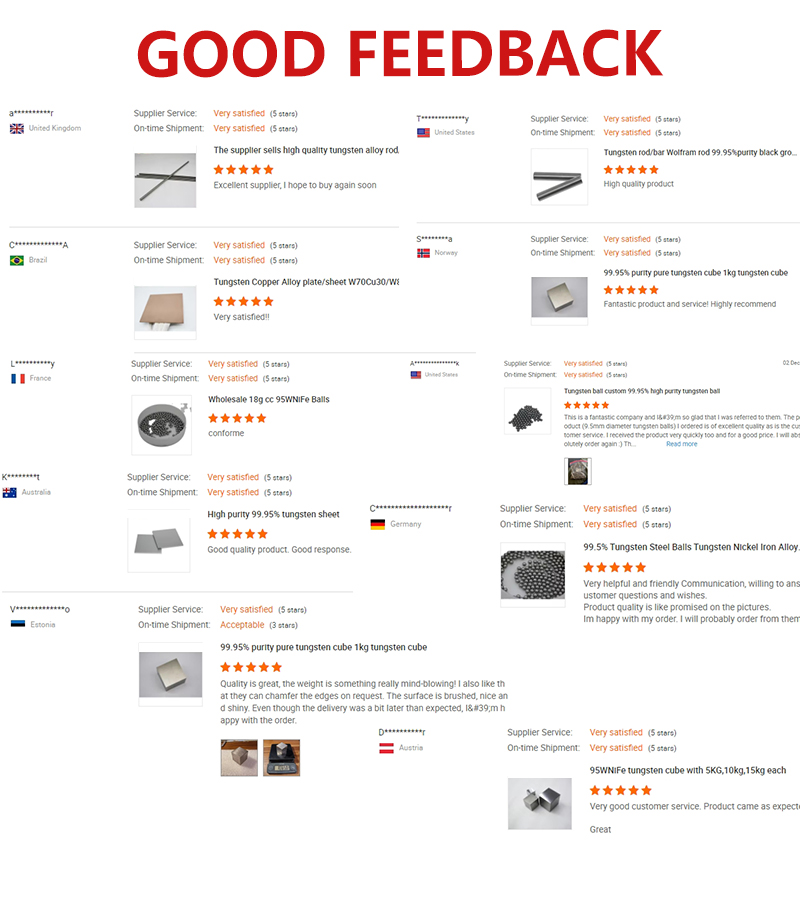

Consistent Performance: Uniform material density prevents localized wear and premature failure.

Enhanced Surface Finish: Achieve superior workpiece results thanks to stable and consistent spark discharge.

Versatile Applications: Perfect for EDM electrodes, resistance welding, and high-temperature mold inserts.

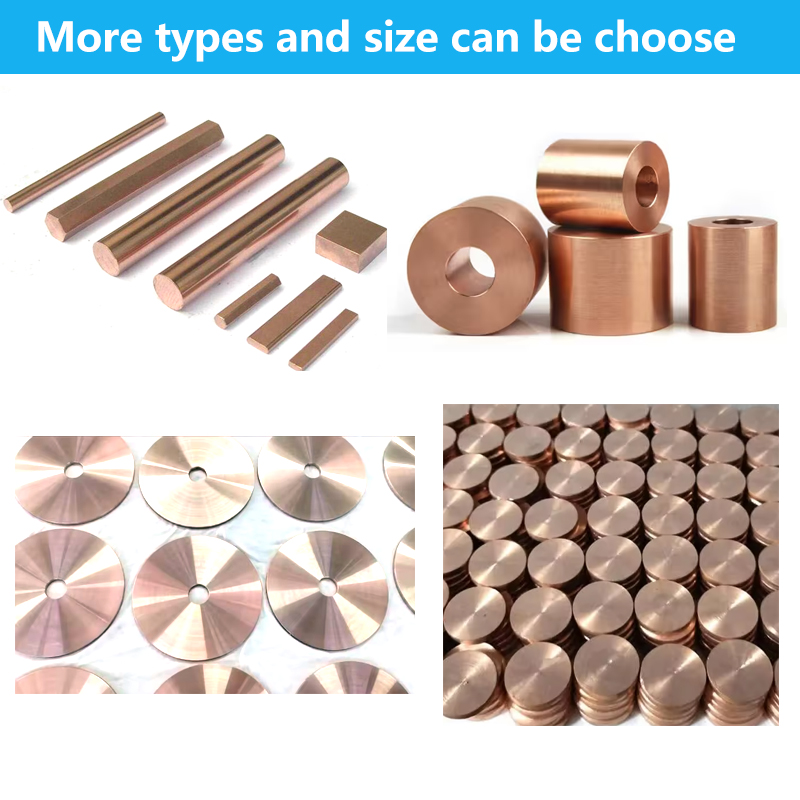

Flexible Specifications: We offer a wide range of outer diameters ($\Phi 22$ to $\Phi 23$) and customizable lengths to match your machinery.

Çima Me Hilbijêre:

1. Hûn dikarin materyalê bêkêmasî li gorî hewcedariya xwe bi bihayê herî hindiktirîn bistînin.

2. Em Reworks, FOB, CFR, CIF, û bihayên radestkirina derî bi derî jî pêşkêş dikin. Em ji we re pêşniyar dikin ku ji bo barkirinê peymanek bikin ku dê pir aborî be.

3. Materyalên ku em pêşkêş dikin bi tevahî verastkirî ne, ji belgeya ceribandina madeya xav heya daxuyaniya pîvana paşîn. (Dê rapor li ser hewcedariyê nîşan bidin)

4. garantî dike ku di nav 24 demjimêran de bersivê bide (bi gelemperî di heman saetê de)

5. Hûn dikarin bi kêmkirina dema çêkirinê re alternatîfên stokê, radestkirina milan bistînin.

6. Em bi tevahî ji bo mişteriyên xwe ve girêdayî ne. Ger piştî vekolîna hemî vebijarkan ne gengaz be ku hûn hewcedariyên we bicîh bînin, em ê we bi dayîna sozên derewîn ên ku dê têkiliyên xerîdar ên baş biafirînin we xapînin.

Pêşangeha kargehê

PAQIJ BÛN

info@zztungsten.com