Product Detail Description:

Elevate Your Precision Machining with Premium W-Cu Alloys

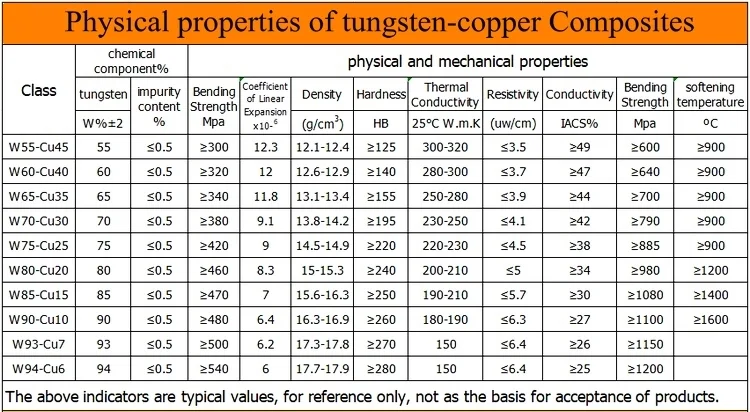

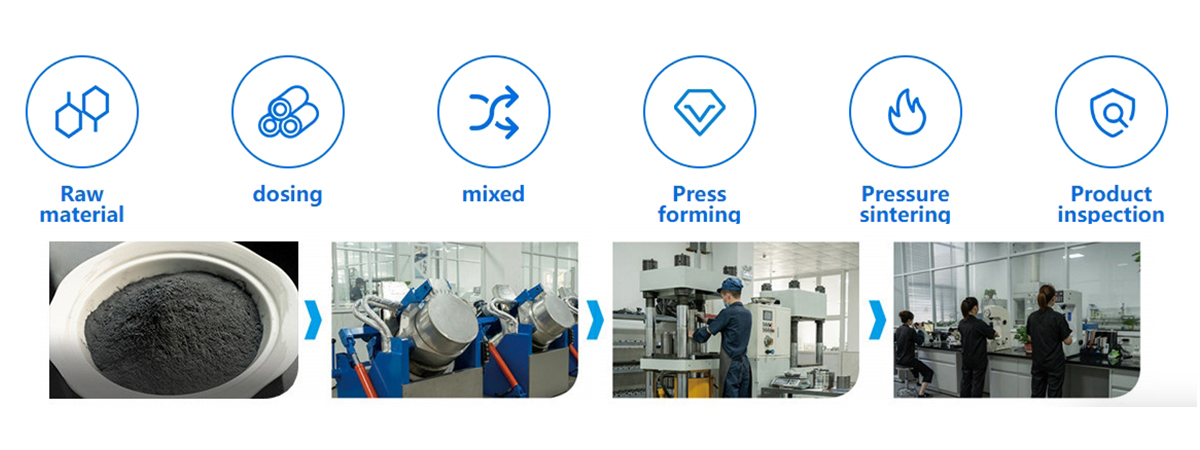

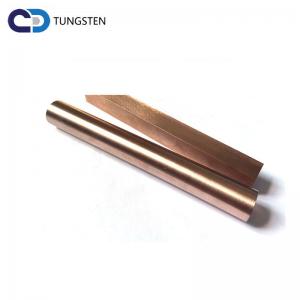

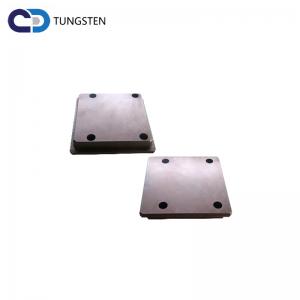

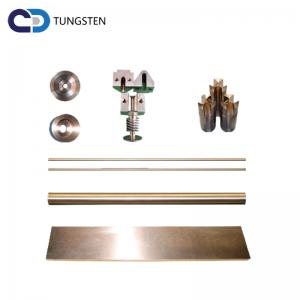

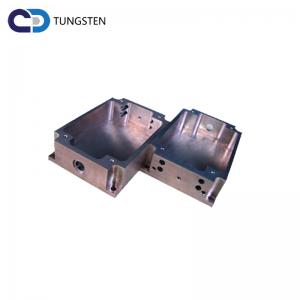

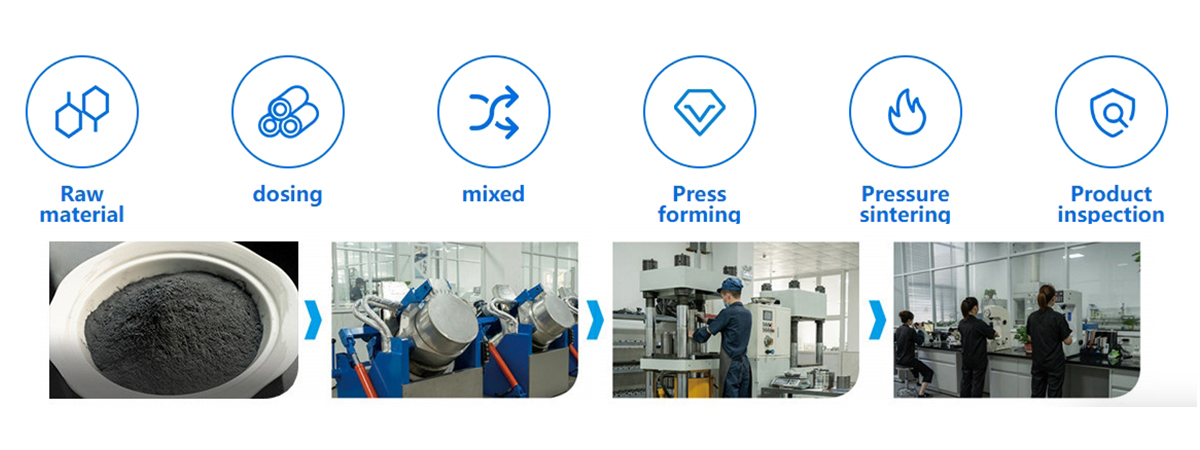

Our Tungsten Copper (W-Cu) alloy components are manufactured using an advanced vacuum infiltration process, ensuring a perfectly uniform microstructure. By combining the high melting point of Tungsten with the superior electrical conductivity of Copper, these parts are engineered for the most challenging EDM (Electrical Discharge Machining) and thermal management tasks.

Key Technical Advantages:

Optimal Density & Hardness: Provides excellent wear resistance and reduces electrode loss during high-speed machining.

Superior Thermal Management: Rapid heat dissipation ensures dimensional stability under extreme temperatures.

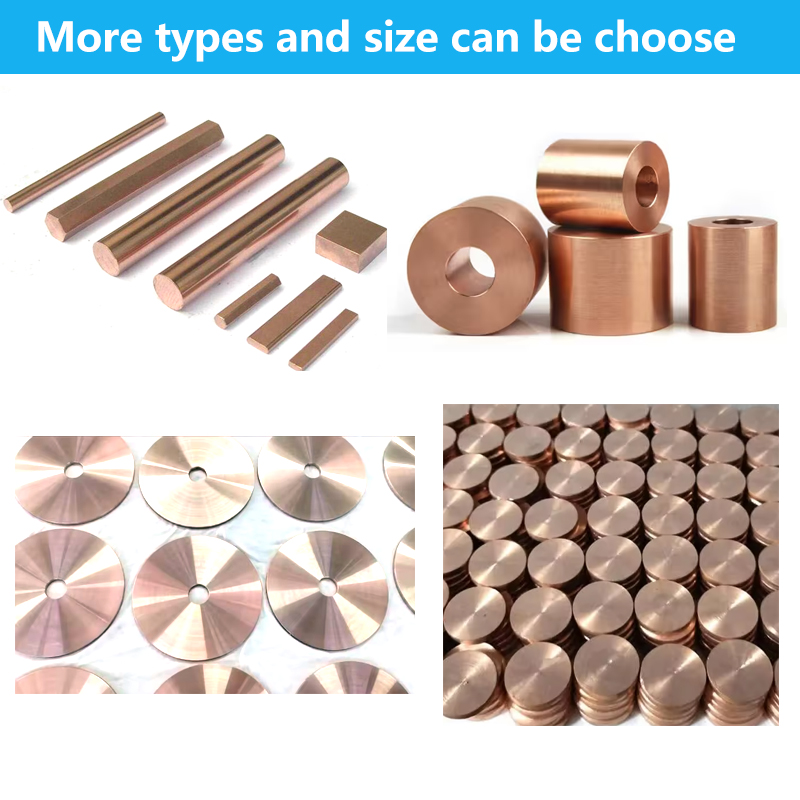

Precision Tolerances: Available in specialized sizes such as $\Phi 22-\Phi 15-23$ and $\Phi 23-\Phi 12-13$ to fit your specific mold designs.

High Arc Resistance: Ideal for high-voltage electrical contacts and heavy-duty industrial applications.

Why Choose Our W-Cu Components?

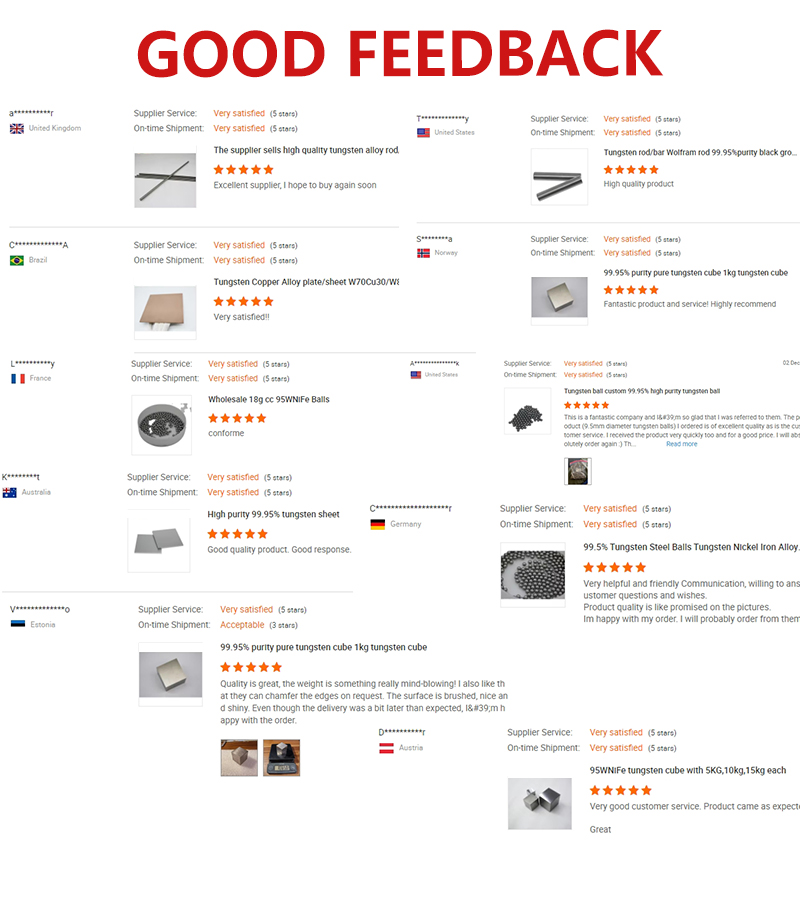

Consistent Performance: Uniform material density prevents localized wear and premature failure.

Enhanced Surface Finish: Achieve superior workpiece results thanks to stable and consistent spark discharge.

Versatile Applications: Perfect for EDM electrodes, resistance welding, and high-temperature mold inserts.

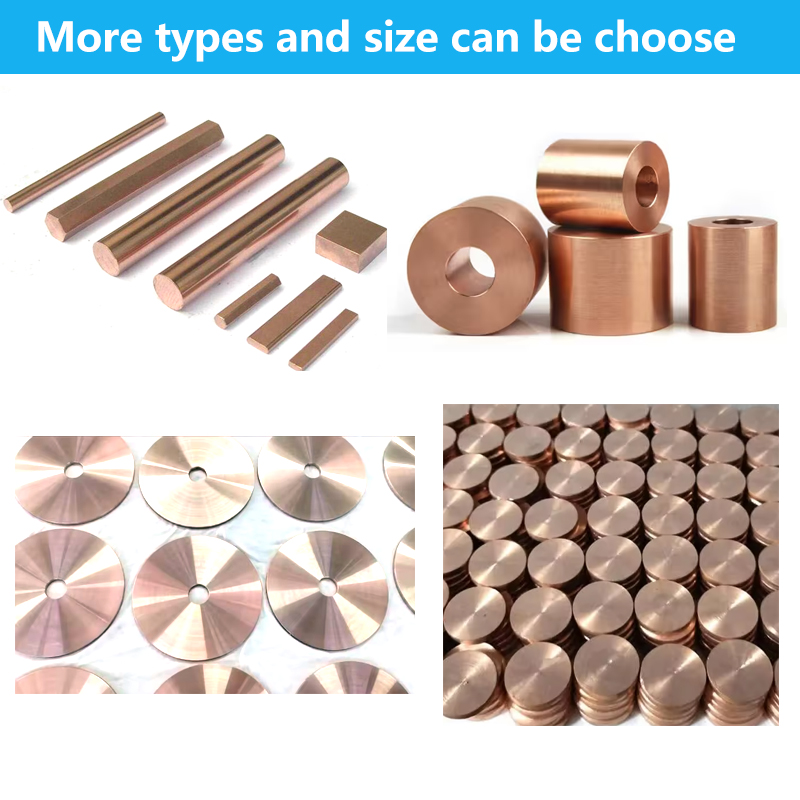

Flexible Specifications: We offer a wide range of outer diameters ($\Phi 22$ to $\Phi 23$) and customizable lengths to match your machinery.

Nahoana no mifidy anay:

1. Azonao atao ny mahazo ny fitaovana tonga lafatra araka ny takinao amin'ny vidiny faran'izay kely indrindra.

2. Izahay koa dia manolotra Reworks, FOB, CFR, CIF, ary ny vidin'ny fanaterana varavarana. Manoro hevitra anao izahay hanao fifanarahana amin'ny fandefasana entana izay tena ara-toekarena.

3. Ny fitaovana omenay dia azo hamarinina tanteraka, manomboka amin'ny taratasy fanamarinana ara-pitaovana manta ka hatramin'ny fanambarana farany amin'ny lafiny farany.

4. antoka hanome valiny ao anatin'ny 24 ora (matetika amin'ny ora iray ihany)

5. Afaka mahazo tahiry hafa ianao, fanaterana fitotoana miaraka amin'ny fampihenana ny fotoana famokarana.

6. Nanokan-tena tanteraka ho an'ny mpanjifanay izahay. Raha tsy azo atao ny mahafeno ny fepetra takinao rehefa avy nandinika ny safidy rehetra, dia tsy hamitaka anao amin'ny fanaovana fampanantenana diso izay hamorona fifandraisana tsara amin'ny mpanjifa.

Fampisehoana orinasa

MIFANDRAISA AMINAY

info@zztungsten.com