Product Detail Description:

Elevate Your Precision Machining with Premium W-Cu Alloys

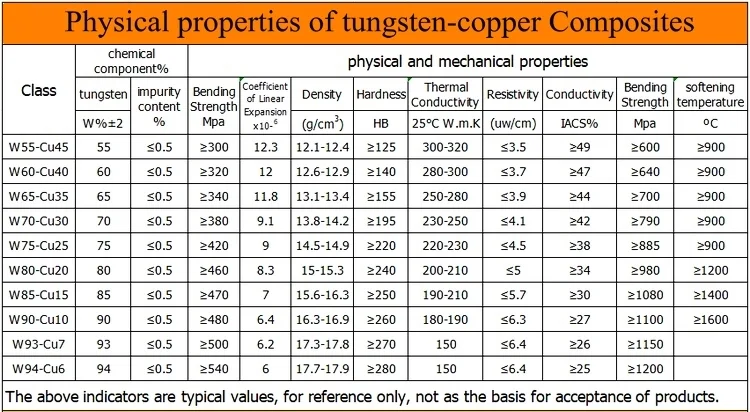

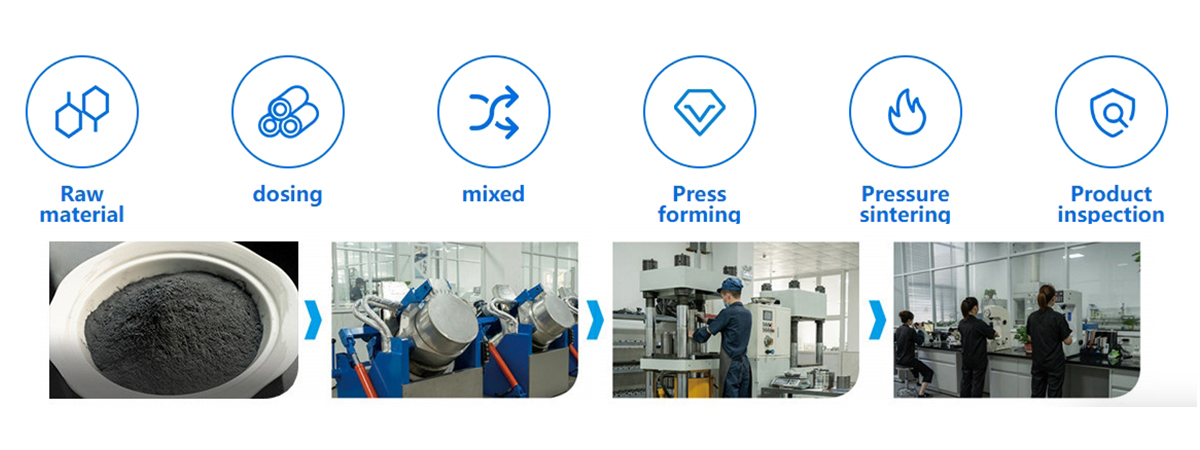

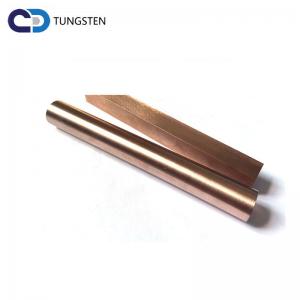

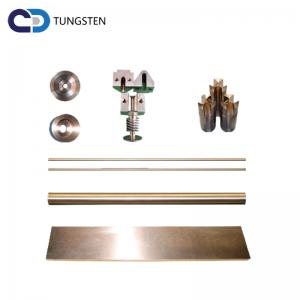

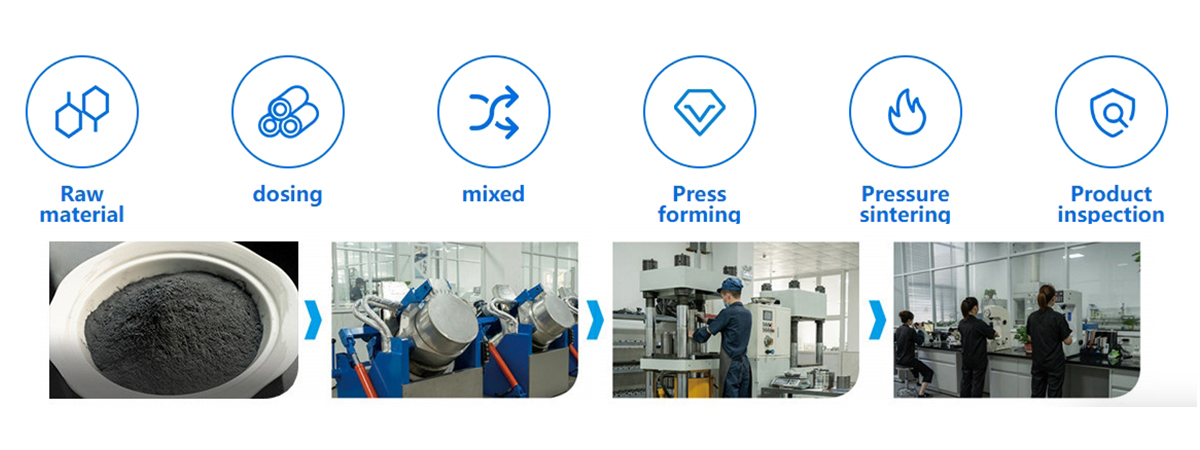

Our Tungsten Copper (W-Cu) alloy components are manufactured using an advanced vacuum infiltration process, ensuring a perfectly uniform microstructure. By combining the high melting point of Tungsten with the superior electrical conductivity of Copper, these parts are engineered for the most challenging EDM (Electrical Discharge Machining) and thermal management tasks.

Key Technical Advantages:

Optimal Density & Hardness: Provides excellent wear resistance and reduces electrode loss during high-speed machining.

Superior Thermal Management: Rapid heat dissipation ensures dimensional stability under extreme temperatures.

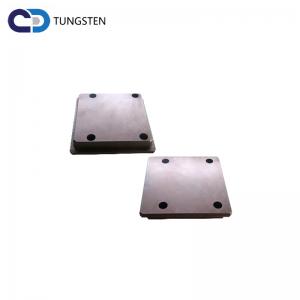

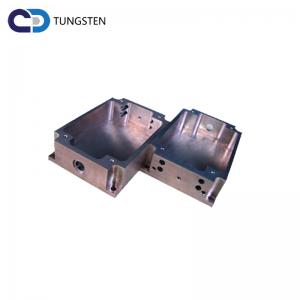

Precision Tolerances: Available in specialized sizes to fit your specific mold designs.

High Arc Resistance: Ideal for high-voltage electrical contacts and heavy-duty industrial applications.

Why Choose Our W-Cu Components?

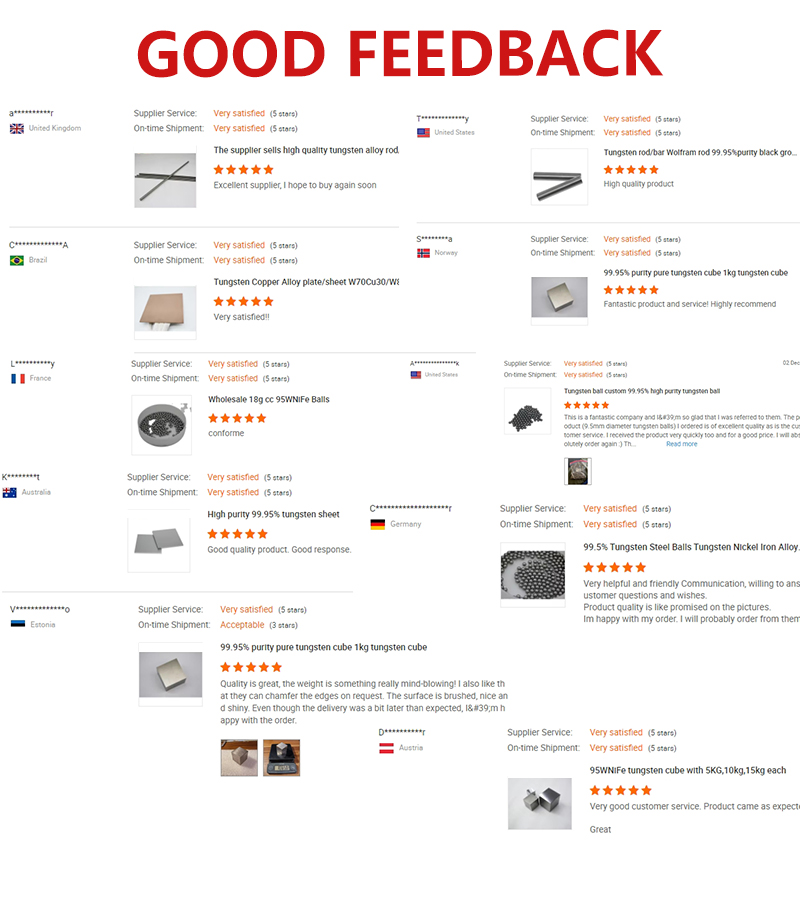

Consistent Performance: Uniform material density prevents localized wear and premature failure.

Enhanced Surface Finish: Achieve superior workpiece results thanks to stable and consistent spark discharge.

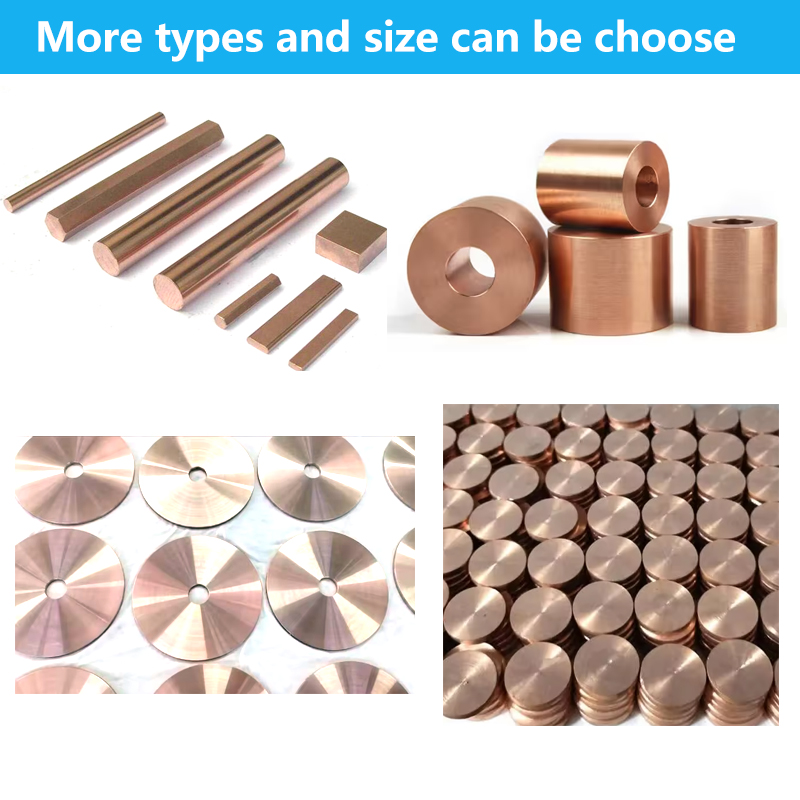

Versatile Applications: Perfect for EDM electrodes, resistance welding, and high-temperature mold inserts.

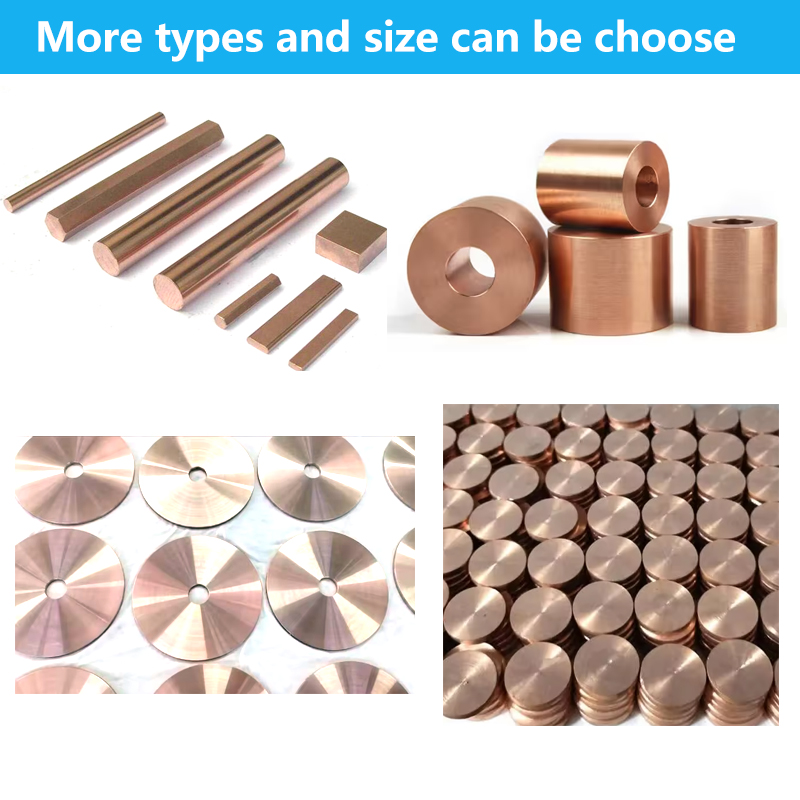

Flexible Specifications: We offer a wide range of outer diameters ($\Phi 22$ to $\Phi 23$) and customizable lengths to match your machinery.

He aha tatou i whiriwhiri ai:

1. Ka taea e koe te tiki i nga mea tino pai kia rite ki to hiahia i te utu iti rawa.

2. Ka tukuna ano e matou nga Reworks, FOB, CFR, CIF, me nga utu tuku tatau ki te tatau. Ka kii atu maatau kia mahi koe mo nga kaipuke ka tino pai.

3. Ko nga rauemi e whakaratohia ana e matou he tino manatoko, mai i te tiwhikete whakamatautau rauemi mata tae noa ki te korero inenga whakamutunga.

4. taurangi ki te tuku whakautu i roto i nga haora 24(i te nuinga o te waa i te haora kotahi)

5. Ka taea e koe te tiki taonga rereke, nga tuku mira me te whakaiti i te wa whakangao.

6. Kua tino whakatapua matou ki o taatau kaihoko. Mena kaore e taea te whakatutuki i o whakaritenga i muri i te tirotiro i nga whiringa katoa, e kore matou e whakapohehe i a koe ma te oati teka e hanga hononga pai ai nga kaihoko.

Whakaaturanga wheketere

WHAKAPAKI MAI

info@zztungsten.com