Product Detail Description:

Elevate Your Precision Machining with Premium W-Cu Alloys

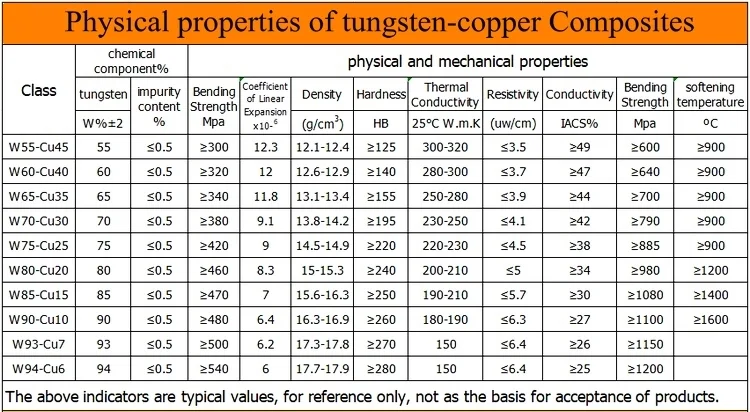

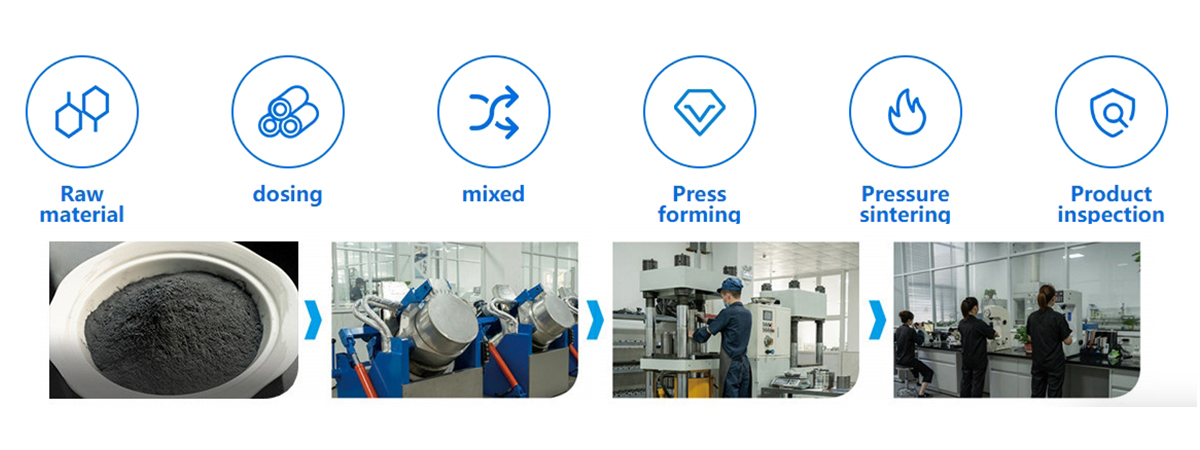

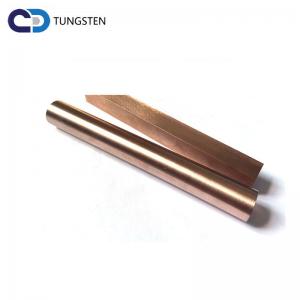

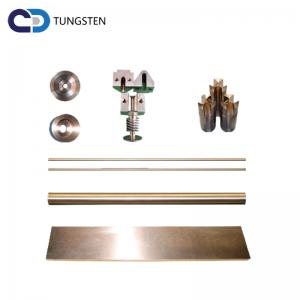

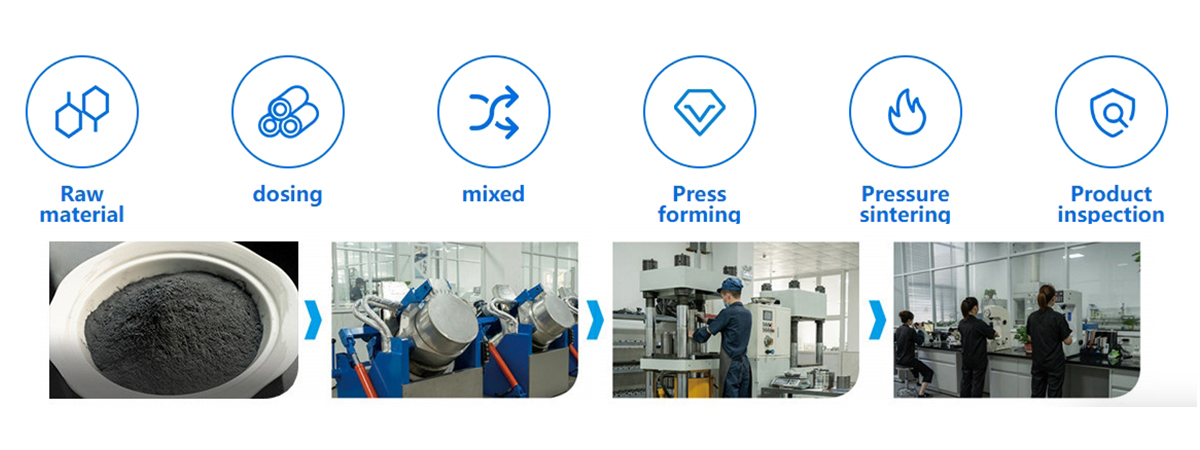

Our Tungsten Copper (W-Cu) alloy components are manufactured using an advanced vacuum infiltration process, ensuring a perfectly uniform microstructure. By combining the high melting point of Tungsten with the superior electrical conductivity of Copper, these parts are engineered for the most challenging EDM (Electrical Discharge Machining) and thermal management tasks.

Key Technical Advantages:

Optimal Density & Hardness: Provides excellent wear resistance and reduces electrode loss during high-speed machining.

Superior Thermal Management: Rapid heat dissipation ensures dimensional stability under extreme temperatures.

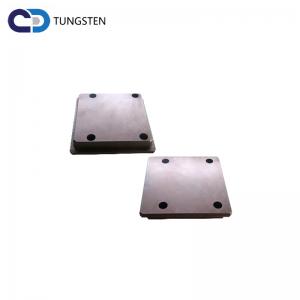

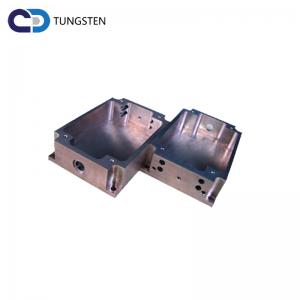

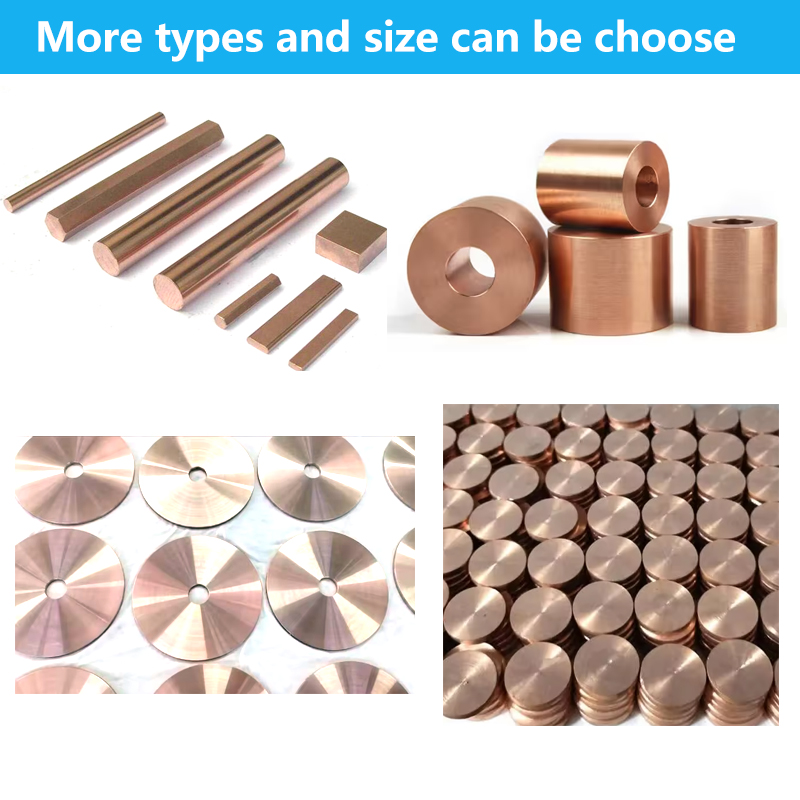

Precision Tolerances: Available in specialized sizes to fit your specific mold designs.

High Arc Resistance: Ideal for high-voltage electrical contacts and heavy-duty industrial applications.

Why Choose Our W-Cu Components?

Consistent Performance: Uniform material density prevents localized wear and premature failure.

Enhanced Surface Finish: Achieve superior workpiece results thanks to stable and consistent spark discharge.

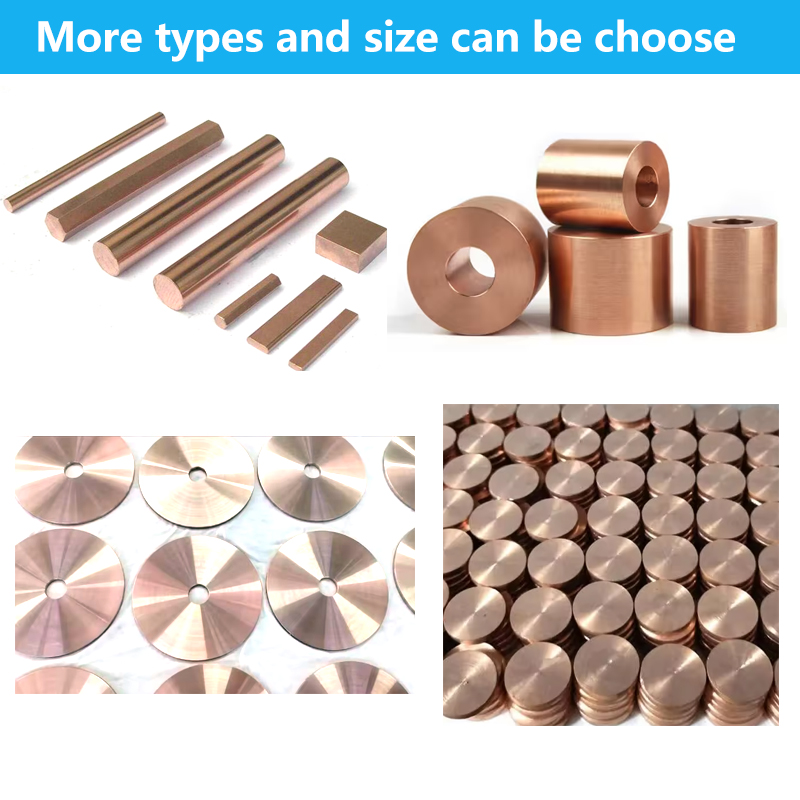

Versatile Applications: Perfect for EDM electrodes, resistance welding, and high-temperature mold inserts.

Flexible Specifications: We offer a wide range of outer diameters ($\Phi 22$ to $\Phi 23$) and customizable lengths to match your machinery.

Sei Tisarudze:

1. Unogona kuwana zvinhu zvakakwana maererano nezvaunoda pamutengo wakaderera.

2. Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekutumira pamusuwo kumasuo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari.

3. Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pagwaro rebvunzo retifiketi kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

4. vimbiso yekupa mhinduro mukati memaawa makumi maviri nemana (kazhinji muawa imwe chete)

5. Unogona kuwana dzimwe nzira dzemasheya, zvigayo zvekutakura nekuderedza nguva yekugadzira.

6. Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

Kuratidzwa kwefekitari

TAURA NESU

info@zztungsten.com